Stories

Making the dirt run off

A building’s outer concrete surface is its figurehead and should be protected and maintained. It is annoying when weather conditions and graffiti threaten its beauty. Surprisingly, it is water that can do the greatest harm – microorganisms, polluting emissions and salts penetrate the surface together with the humidity and gradually attack the basic fabric of the building. “Back in the days concrete had to fulfill only practical requirements. Today, however, it has become a design element that has to satisfy optical demands as well”, Karsten Roszak, concrete-engineer at RECKLI, explains. Roszak is responsible for everything pertaining to concrete itself – from the use of the right release agents between concrete and formliner to the protection and maintenance of concrete surfaces.

RECKLI offers surface protection systems that immunize exposed concrete surfaces against water, dirt and graffiti. The transparent protective film seals not only any kind of concrete surface but also clinker, bricks, sandstone, sand-lime brick and granite. They can be applied to both old and young concrete, are UV-resistant and water-vapor permeable. Additionally, they reduce the penetration of aqueous or oily staining into the concrete. For absorptive concrete, effect-impregnation can be used which protects against smudging while creating a dull to silky shine and intensifies the concrete’s color effect. Both product lines also prevent freeze-thaw damages.

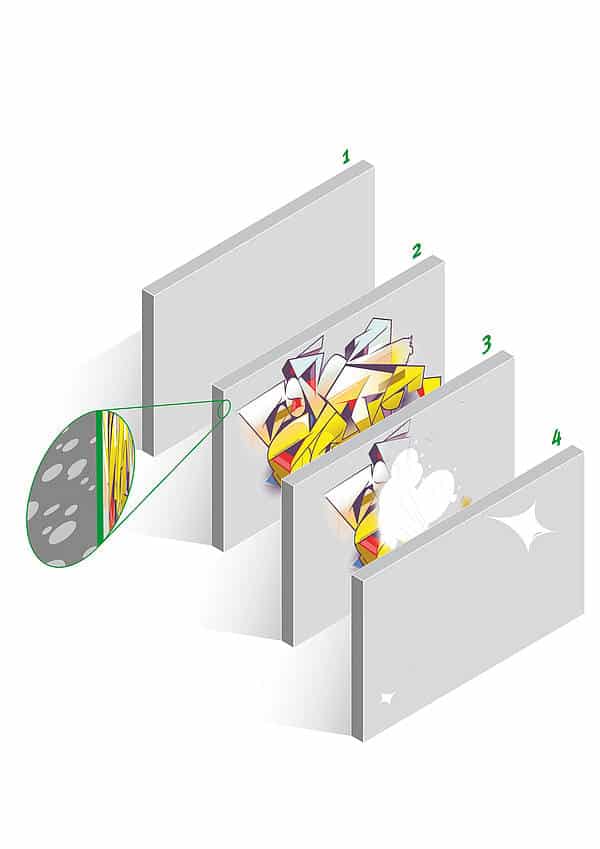

A special kind of surface protection is offered by RECKLI Graffix. The transparent impregnation film protects the basic fabric of the building for a long period of time and can be applied onto freshly casted concrete without affecting its looks or texture. The durability of the protective film makes the maintenance of the concrete surface easy and economically efficient. Using RECKLI Graffix Cleaner, graffiti can be easily removed without destroying the protective film. Roszak explains that the products are continuously enhanced since paint manufacturers have ongoing programs to provide improved adhesion.. The impregnation solutions are tested on concrete surfaces in the in-house laboratory to keep pace with the paint industry.