Stories

Eye-catcher guaranteed

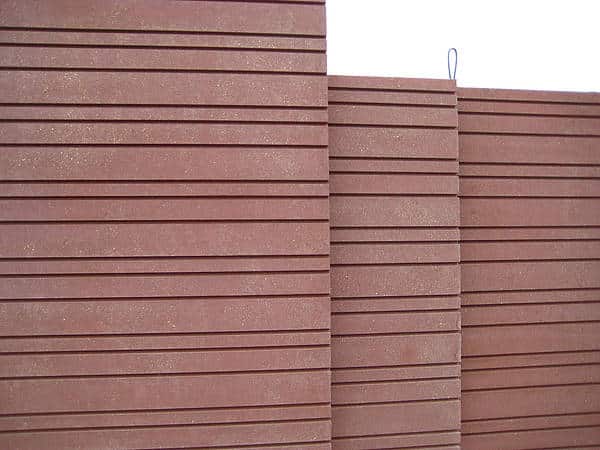

If you associate washed concrete only with the prefab buildings built during the 60s and 70s, you have missed out on something. Final deactivation of concrete and acidification products can turn the supposedly outdated concrete into a modern design element.

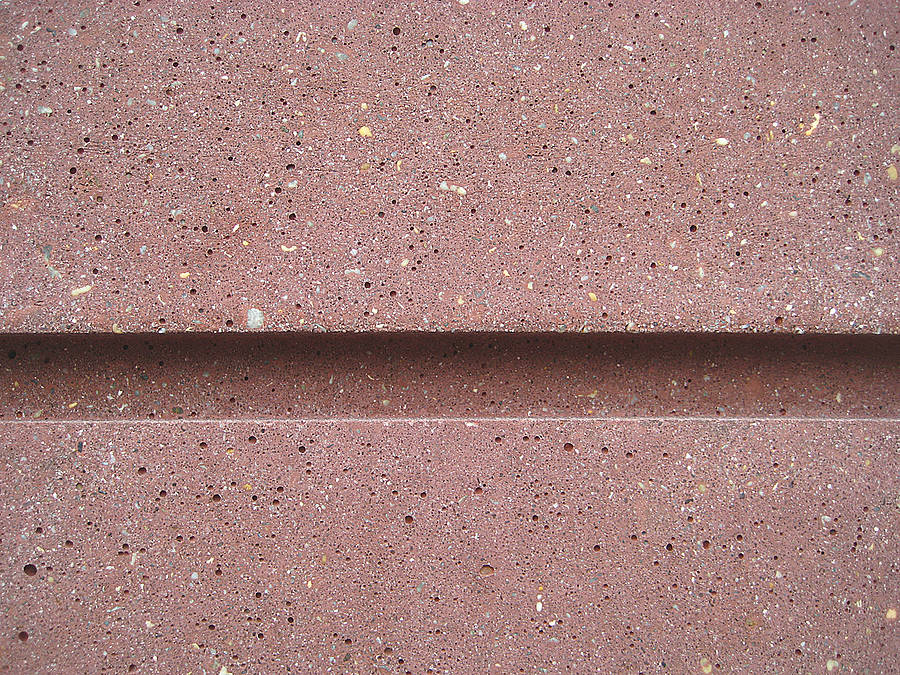

Architects have started to use washed concrete again to create optical effects. This construction material offers well-known practical advantages, like skid resistance, which is why it is often used for floor spaces. Washing out the concrete dissolves the topmost cement skin and exposes the underlying aggregate. The concrete surface becomes rougher which creates a better foothold.

Washed concrete can be manufactured using a negative- or positive process through the application of a final activation component either onto the formwork before filling in the concrete or by spraying it onto the fresh concrete after concreting. RECKLI offers the respective surface retarders for both processes. The positive process is best suitable for in-situ application , such as artificial stones while the negative process is used for prefabricated parts and concrete surface elements. Depending on the process, the products react on a solvent or water basis and guarantee a homogeneous washing pattern. The surface retarders can be used to create fine and rough surfaces with different washing depths while being easy to use and economically efficient.

A further kind of surface-treatment is acidification. During this process, an acidic solution is applied to the fresh and pre-wetted concrete. The acid reacts with the topmost cement skin and allows for the washing-out of the surface at a micro level. The effect achieved with this technique is a slightly roughed-up surface that optically resembles sandstone. The architectural bureau Bahl and Partner, from Dortmund used this effect when building the RAG Montan Immobilien headquarters. The base area of the buildings’ concrete walls in the patio is adorned with the names of all of Montan Immobilien’s completed projects. Instead of simply painting the letters onto the wall, they were imprinted using acidification and RECKLI formliners. The letters’ sharp edges ensure a clear typeface while the roughed-up surface refines the concrete optically.